International Trucks

New & Used Heavy-Duty, Severe-Duty & Medium-Duty

International® has been a leader in the commercial vehicle industry since 1902. Today, they offer a complete lineup of medium-, heavy- and severe-duty trucks purpose-built to move your business forward. This means that whatever the job, there’s an International truck built for it. From construction, towing and refuse applications to local delivery and specialized hauling, International prides itself on knowing and understanding your needs and delivering solutions that help your business run at its best — no matter the industry. Rush Truck Centers has more than 50 International dealerships nationwide with new and used International truck inventory in stock and ready to meet your needs.

Drive Now, Pay Later Promotion

No Payments for Up to 90 Days on International Trucks and IC Buses

Offer End Date: December 31, 2026

International Heavy-Duty Trucks

Take the show on the road with International’s heavy-duty truck models. Designed for life on the highway, the International LT® Series and RH™ Series are ready to go the distance with a GVW of up to 60,000 lbs. And International always keeps the driver’s needs in mind by ensuring their heavy-duty truck models are not only safe and comfortable for driving long distances, but also fun to drive.

International Severe-Duty Trucks

International’s severe-duty trucks are built to work for a living. The durable and rugged HV™ Series and HX® Series models are tough enough to take on the most punishing of job sites. With cabs that keep drivers comfortable, block out distracting noise and still ensure maximum visibility, these severe-duty trucks pack a serious punch.

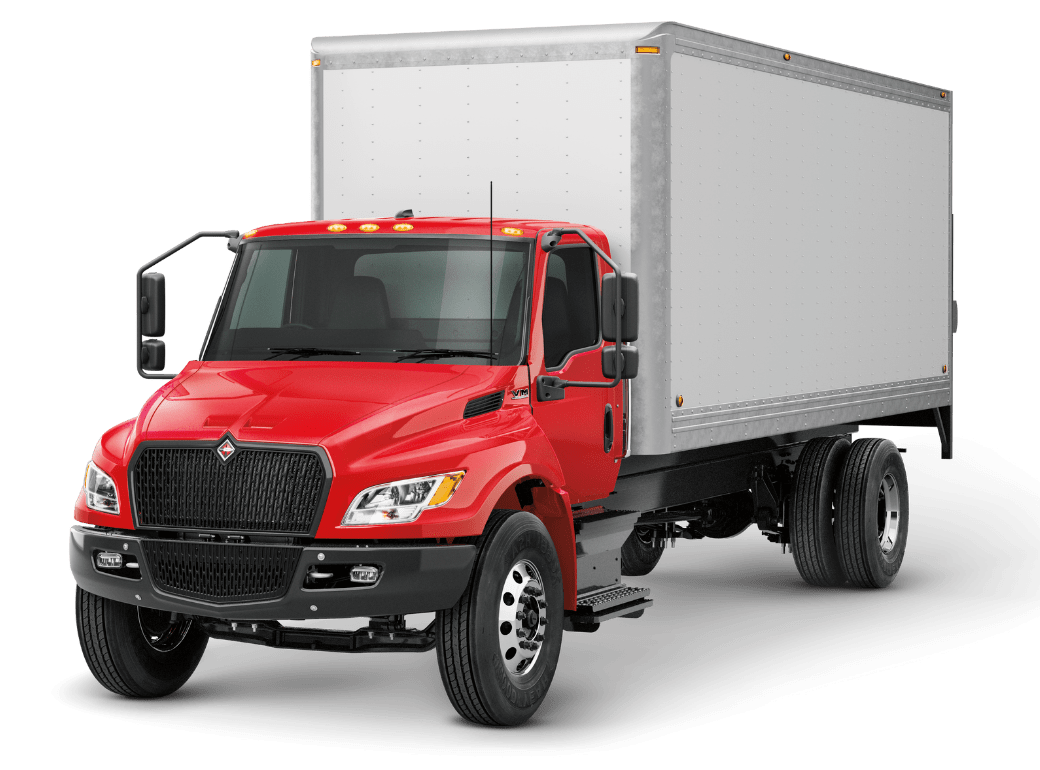

International Medium-Duty Trucks

International’s medium-duty models offer versatility and maneuverability without sacrificing the durability of International’s bigger classes. Whether you need a vehicle that effortlessly navigates busy job sites or zips through city streets, International’s MV™ Series and CV™ Series models can handle it.

International Electric Trucks

The revolutionary International eMV™ Series is built on the same proven foundation as the diesel MV Series while offering the sustainability benefits of an electric vehicle. Perfect for medium-duty applications, the eMV offers up to 342 peak hp and 1,737 lb.-ft. of torque while delivering zero emissions.

Build Your Own International Truck

Put a personal spin on your favorite International Truck in the configurator tool. This tool allows you to configure most International models in a variety of ways including exterior paint, interior trim, powertrain, accessories and more.

Frequently Asked Questions

-

International trucks are manufactured by International Motors, LLC, a global commercial vehicle manufacturer. International trucks are built in North America and supported by an extensive dealer and service network, helping ensure reliable parts availability, service support, and long-term uptime for fleets and owner-operators.

International has five assembly and manufacturing plants in the United States and Mexico:

- Escobedo Assembly Plant (Escobedo, Mexico): Produces a full range of Class 8 vehicles

- San Antonio Manufacturing Plant (San Antonio, Texas): Produces Class 6 through 8 diesel and electric vehicles

- Springfield Assembly Plant (Springfield, Ohio): Builds CV Series, MV Series and HV Series trucks

- Huntsville Powertrain Manufacturing Plant (Huntsville, Alabama): Supplies diesel engines to the Springfield and Escobedo assembly plants

- Tulsa Bus Plant (Tulsa, Oklahoma): Manufacturers IC Bus CE Series school buses and commercial buses

-

Yes. International trucks are engineered for a wide range of applications, including long-haul, regional haul, construction, towing, utility, municipal, delivery and other vocational uses. Our truck sales experts can help match the right International model and configuration to your specific operational requirements.

-

International trucks offer a range of powertrain options, including International engines and integrated powertrain solutions designed to improve fuel efficiency, performance and uptime. Engine availability varies by model and application, and our sales experts can help determine the best option for your operation.

- International S13® Integrated Powertrain – LT Series, RH Series, HX Series, HV Series

- Cummins X15 Diesel – LT Series, HX Series

- Cummins B6.7 Diesel – HV Series, MV Series

- Cummins L9 Diesel – HV Series, MV Series

- International 6.6L Diesel – CV Series

-

Yes. The International eMV Series is an all-electric, zero-emissions solution for medium-duty applications. The eMV is designed to support sustainability goals while maintaining productivity and performance. Availability may vary by region and application, so contact your nearest Rush Truck Centers location for current inventory and options.

-

Yes. International trucks are designed to be highly customizable and can be upfitted for a wide range of vocational needs. We work with trusted upfit partners to help configure trucks for construction, towing, delivery, utility and other specialized applications.

-

The price of an International truck varies based on model, configuration, engine options, upfits, and whether the truck is new or used. For a personalized quote and to explore financing options, please view our inventory and contact your nearest Rush Truck Centers dealership today.

-

Yes. We offer flexible financing solutions for both new and used International trucks. Financing through Rush Truck Financing lets you combine your vehicle, preventive maintenance, extended protection plan and GAP into one convenient monthly payment.

-

New International trucks typically include manufacturer warranty coverage, while used trucks may be available with aftermarket warranty options depending on condition and age. Our truck sales experts can explain available warranty programs and help you choose coverage that fits your ownership goals.

-

DriverFirst™ is International's user-centric approach to designing and optimizing its vehicles, putting the needs and wants of the driver at the forefront. Through a deeper understanding of the different types of drivers, their capabilities and their preferences, International designs trucks that drivers want to drive.

-

Severe-duty trucks are Class 8 heavy-duty trucks built for vocational use. Typically designed to be more durable and haul heavier loads, severe-duty trucks are designed for specific applications, such as dump trucks, mixer trucks, crane trucks, snowplows, fire and rescue trucks, tow trucks and more. International’s HV and HX Series models are considered severe-duty trucks.

-

Rush Truck Centers is the largest commercial vehicle dealership in the country and currently operates 52 full-service International dealerships in Arkansas, Georgia, Idaho, Illinois, Indiana, Kansas, Missouri, North Carolina, Ohio, Tennessee, Utah and Virginia.

-

Rush Truck Centers currently has 56 dealerships certified to service and sell parts for International trucks, 52 of which are Prestige Certified by International.

Prestige Certified dealers have passed rigorous standards set by International that ensure customers receive the best sales, service, parts and leasing experience possible.